The EG600CE is the Professionals’ bike lift of choice

EG600CE Motorcycle Lift – Premium Performance from RS Workshop Equipment

We’re currently offering a special promotion on ALL motorcycle lifts, with a spotlight on the EG600CE – a high-performance, professional-grade lift from Italy.

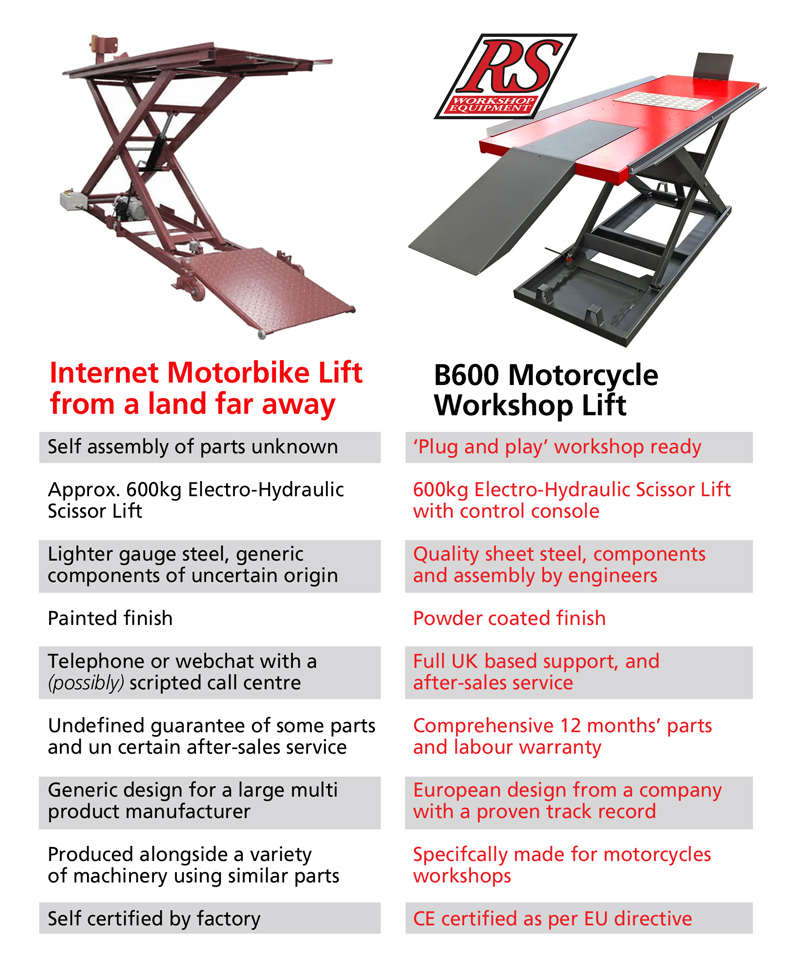

Why Choose the EG600CE Over Cheaper Imports?

While budget motorcycle lifts from the Far East may seem appealing at first glance, there are several critical factors that set the EG600CE apart:

Benefits / Advantages of the EG600CE:

- Superior Build Quality: Constructed with robust materials for long-term durability, the EG600CE is designed to handle heavy daily use without compromise.

- Precision Engineering: Smooth, reliable lifting operation thanks to high-quality hydraulic systems and safety mechanisms.

- Higher Safety Standards: CE-certified with multiple safety locks and anti-slip platforms, ensuring technician safety and peace of mind.

- Ergonomic Design: Designed for professional use with thoughtful features like front and rear drop-out panels for easier wheel servicing.

Pros vs. Far-Eastern Budget Alternatives:

| Feature | EG600CE | Budget Alternatives |

|---|---|---|

| Build Quality | Heavy-duty steel frame | Lightweight, lower-grade materials |

| Lifting Capacity | Up to 600kg | Often limited to ~400kg |

| Safety Certifications | CE Certified | Often non-compliant or uncertified |

| Service & Spare Support | UK-based, quick parts access | Unreliable or delayed spare parts |

| Long-Term Reliability | 10+ year lifespan | Prone to failure in 1–3 years |

| After-Sales Support | Dedicated technical support | Minimal or nonexistent support |

Why RS Workshop Equipment Is the Go-To Choice

With over 20 years of experience, RS Workshop Equipment has built a strong reputation among main dealers and independent workshops alike. Here’s why:

- ✅ Trusted by Major Dealerships: RS supplies motorcycle lifts and workshop gear to several of the UK’s top OEM franchises.

- ✅ Expertise You Can Rely On: Our team understands the demands of a busy workshop and provides tailored advice to ensure you get the right equipment.

- ✅ Exceptional Support: From installation to maintenance, we offer unmatched technical support and fast access to parts.

- ✅ Complete Workshop Solutions: Beyond lifts, RS offers a full range of motorcycle workshop machinery—benching, tyre changers, brake testers, and more.

Summary

Choosing the EG600CE from RS Workshop Equipment is an investment in safety, efficiency, and long-term reliability. While cheaper alternatives may undercut on price, they simply can’t compete on quality, support, or peace of mind—making RS the preferred supplier for professionals who take their craft seriously.

EG600CE Motorcycle Lift vs. Budget Far-Eastern Lifts: Comparison Chart

| Feature | EG600CE | Far-Eastern Budget Alternatives |

|---|---|---|

| Build Quality | Heavy-duty construction, long-lasting | Thin metal, lower durability |

| Lifting Capacity | Up to 600kg – supports larger bikes | Typically 400kg or less |

| Certification | CE certified, meets UK/European standards | Often uncertified or questionable origins |

| Safety Features | Multi-point locking, anti-slip surface | Minimal or no locking systems |

| Maintenance & Spare Parts | UK-based, fast supply and technical support | Hard to source, long wait times |

| Longevity | 10+ years of reliable performance | Often shows faults within 2–3 years |

| Ergonomics | Drop-out panels, technician-friendly design | Basic flat platform, no convenience tools |

| After-Sales Support | Industry-leading, UK-trained specialists | Typically unavailable or outsourced |

Trusted by main dealers and independent workshops alike, the EG600CE from RS Workshop Equipment sets the benchmark in professional motorcycle lifting.

- CE-Certified Safety & Stability

- 600kg Capacity for All Bikes

- Rear Drop-Out Panel for Ease of Service

- Heavy-Duty Build for Long-Term Reliability

- Backed by Over 20 Years of Workshop Expertise

- 12 month’s comprehensive warranty

- Unrivalled after-sales service

Why Choose RS Workshop Equipment? With two decades of hands-on experience, we are proud to be the trusted supplier for major motorcycle brands and independent garages across the UK. From expert advice to after-sales support, our dedicated team ensures you always get the right tool for the job.

Act Now – Limited-Time Promotion!

Contact us today to reserve your EG600CE or discover more speak to our workshop machinery specialists.

Testimonials

“We’ve used RS Workshop Equipment for over 15 years. Their gear just works—and if anything ever does go wrong, they’re only a phone call away.”

– Mark L., Independent Motorcycle Garage, Kent

“The EG600CE is the most reliable lift we’ve ever installed. It’s solid, safe, and does exactly what we need day in, day out.”

– Steve H., Motorcycle Dealer, Midlands

“Far-eastern imports failed on us within months. RS supplied the EG600CE and it hasn’t missed a beat in 3 years. The difference is night and day.”

– Rachel P., Multi-Brand Service Centre, Yorkshire