Motorcycle Wheel and Tyre Maintenance

Motorcycle wheels and tyres all look remarkably alike to an untrained eye or inexperienced rider; however, a professional mechanic or bike enthusiast will tell how much of difference there can be between the vast number of rubber and wheel options in the marketplace. Riders can be loyal to a brand or will make a purchase based on price, a review, and recommendations, but choosing the right equipment for a motorcycle is essential to getting the most out of the bike performance and enjoyment of riding one. If the handling on your motorbike suddenly feels different, or the chain is making strange noises it could be down to the tyres, maybe they are wearing out asymmetrically? In this article we look a little closer at some of following topics relating to motorcycle tyre and wheel maintenance:

- Motorcycle Tyres and Markings Motorcycle Tyre Pressure Motorcycle Wheel Alignment Mounting and Changing Motorcycle Tyres and Wheels Motorcycle Wheel Balancing

Motorcycle Tyres and Markings

Tyres offer riders different things, they should match and be the correct size (speed and load ratings) for the motorcycles make and model, if in doubt, always seek professional advice or refer to the manufacturer’s recommendations. The technology of a tyre impacts on its durability, performance, load, weather capability, and what the bike generally is used for. Motorcycle tyres should all have figures printed on them which provide us with a lot of information, for example: 180/55 ZR17 (73W). In this case ‘180’ tells us how wide the tyre is in mm, 55% is the profile height of 180mm, which equates to 99mm. ZR17 relates to the size of the rim in inches (17), ZR refers to the (Z) tyre speed rating and construction type R (radial), finally, 73W is the speed and load index, if this figure is in brackets, it means the tyre is capable of speeds in excess of the figure, no brackets mean it’s a maximum rating.

Motorcycle Tyre Pressure

Before setting off it is good practice to check the motorcycles tyre pressure, always do this when the tyres are cold, and never exceed the maximum load. Follow the tyre pressure setting (PSI) recommendations listed on manufacturer manuals, always use a good quality pressure gauge that holds a reading.

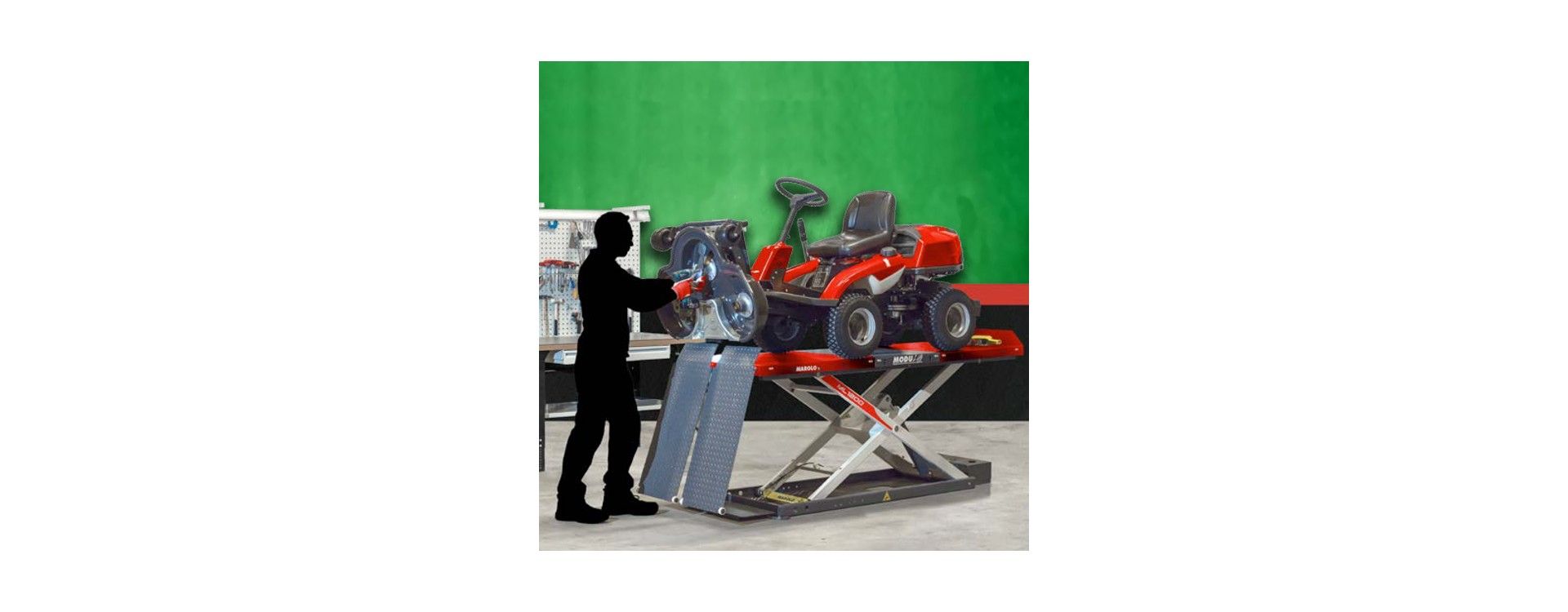

Overinflating motorcycle tyres will result in accelerated tyre wear. Underinflated tyres can result in irregular tread wear, cracking, poor cornering, punctures, and loss of control which could be fatal. Repeated loss of tyre pressure can signal another problem. Visually inspect both the wheel and tyre closely, to assist use a hydraulic motorcycle lift if available, if in any doubt seek the advice of an expert.

Whenever the rear bike wheel is removed, or the belt or chain adjusted, you will need to align the motorbike wheels again. If you do not have the correct motorcycle workshop equipment to check wheel alignment, like a yoke, centre or rear paddock stand for lifting the bike, it’s important to seek the advice of a professional. An incorrectly aligned wheel will can cause expensive irreversible damage, even malfunction whilst in use which could be fatal.

Motorcycle wheel alignment is the position of a rear wheel in the swing arm, and its alignment with the front wheel and frame of the bike.

Mounting Wheels and Motorcycle Tyre Changing

Some motorcycle tyre punctures can be repaired, but an exterior, sidewall or temporary repair should never be attempted. Only specially trained persons should mount tyres using professional motorcycle workshop equipment. Mounting and changing wheels and tyres incorrectly can cause tyre explosion and serious injury, always wear the appropriate PPE.

Common tools required to carry out motorcycle tyre changing include, paddock stands or a swing arm pivot stand, robust bead breakers to force the tyre rim, a motorcycle wheel balancer, tyre lever kit with protectors, and a valve key.

To avoid irreversible damage, excessive tyre wear and vibrations whilst riding, all motorcycle wheels need to be balanced before use and rebalanced once a tyre is either replaced or removed.

Tyres are made to exacting standards but there is always an imbalance between the rim and a new tyre. Balancing by use of weights is best carried out by a professional motorcycle balance stand or computerised wheel balancer with a quick and easy mounting system, as it can detect which part of the wheel rim needs additional weight.

Refer to the wheel manufacturer’s instructions for approved wheel weights. Once the motorcycle wheel is on the balancer, remove any old wheel weights and spin the wheel to start the balancing process.